Are you interested in learning about the different types of CNC machines?

CNC, or Computer Numerical Control, is used to control automated machine tools. This type of machinery is widely used in manufacturing, making it an essential part of many industries.

From the different types to the various multi-axis models, this article will discuss the 12 most common types of CNC machine and help you decide which one is best suited to your needs.

What is a CNC Machine?

A computer numerical control machine is a computer-controlled device that allows you to create precise parts and components. It works by reading directions from pre-programmed software, called G-code, which controls the movements of the machinery.

CAD and CAM software is used to create designs which are then translated into this G-code, which instructs and controls the machining process. This results in accurate cuts and shapes with a quality finish at minimal error rates.

This versatility and precision make CNC machines popular in industries ranging from manufacturing to engineering. That being said, there are a variety of different CNC machines, and to get optimal results you must pick a machine that best suits your requirements.

Common Types of CNC Machine

CNC machines are a great way to accurately produce parts of all shapes and sizes, but which type of machine should you be using?

Here at Link Business, we offer a range of subcontract CNC machining services across the West Midlands and UK, including CNC Turning and Milling. If you’re unsure which type of CNC machine to use, our expert team is on hand to help you determine the right machining processes based on the requirement of your project.

These versatile tools allow for the quick creation of complex parts with great accuracy that would otherwise be extremely difficult using traditional methods.

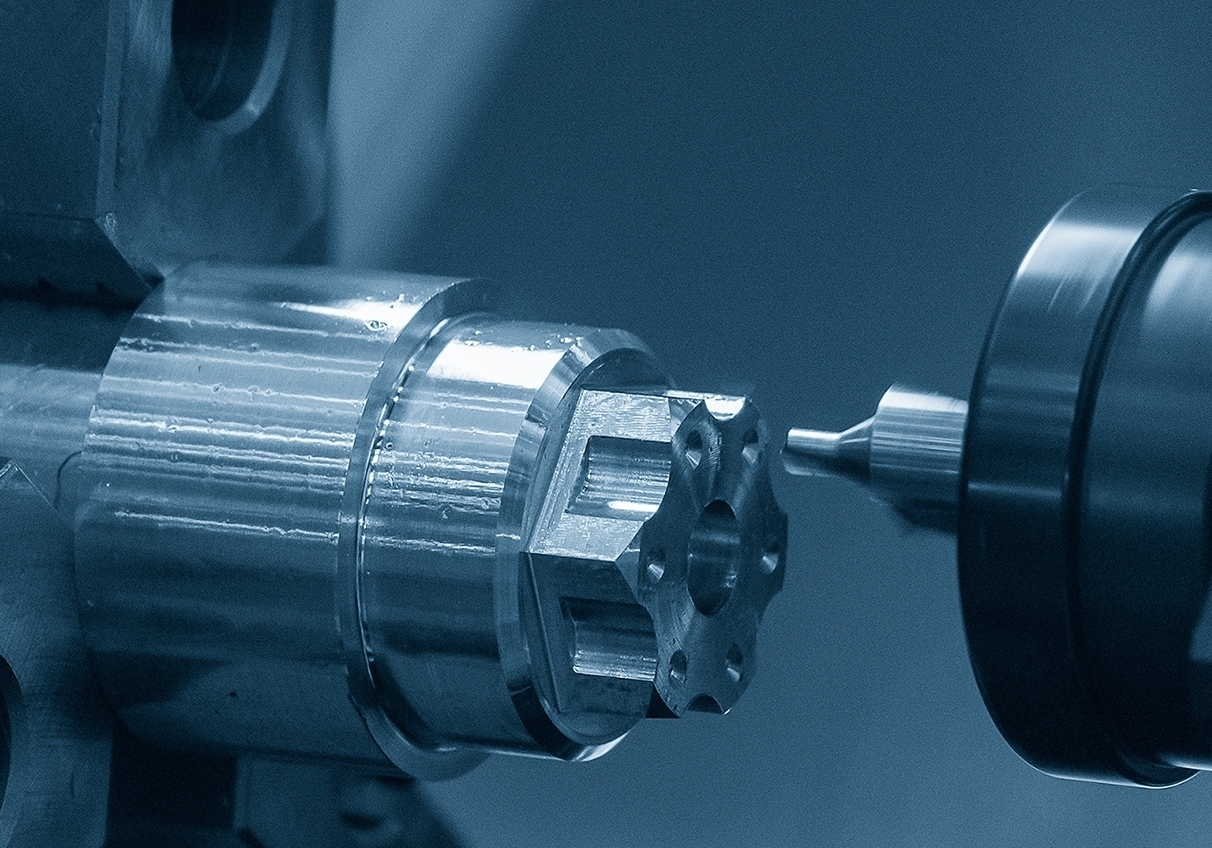

CNC Lathe and Turning Machines

Ideal for various processes like cutting, sanding, facing, drilling, turning, and knurling, CNC lathe machines can be used to quickly and precisely create shapes or components from a wide range of materials. At Link Business, we provide this service for a variety of ferrous, non-ferrous and exotic materials, like plastic.

CNC turning involves a non-rotary tool moving along a rotating workpiece in a helical/spiral path to remove material from the surface. This process is much faster than manual lathing and offers greater precision at lower costs.

Turning is commonly used to produce cylindrical-shaped workpieces, but can also be used for square or hexagonal-shaped materials.

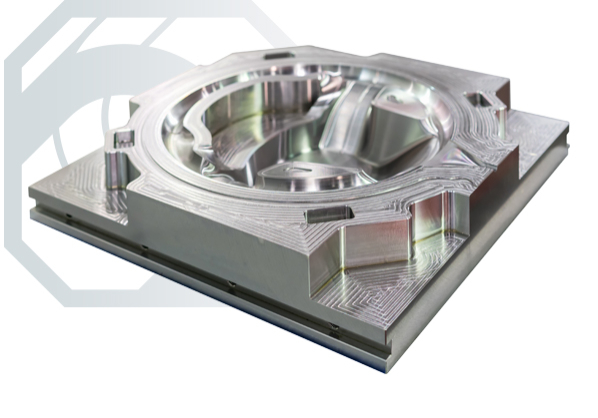

CNC Milling

Milling is a machining process in which a rotating tool removes material from the surface of a stationary workpiece to create complex shapes. They come in many different varieties, including vertical (ideal for milling intricate details) and horizontal spindle (ideal for milling deeper grooves) designs, or automatic tool changer CNC machines (which switch between multiple tools without human intervention).

CNC milling machines are incredibly powerful pieces of equipment that provide consistent and accurate results, ideal for mass production. They can quickly turn ideas into reality, making them an essential part of modern manufacturing processes. With the right setup, they can replace traditional lathes for certain operations.

CNC Router

Similar to a Milling machine, a CNC router is a cutting tool used to carve out parts and components from a workpiece. However, unlike a CNC machine (which is used to cut tougher materials), a router is used for softer materials like wood, aluminium, foam, and plastic. It is one of the most popular CNC machines available due to its ability to quickly cut complex shapes. Compared to their counterparts, CNC routers reduce waste, increasing productivity and accuracy.

These machines are typically equipped with an automatic tool changer, which allows for quick changes between different tools depending on the job at hand. The machine also has a large working area that can accommodate large and small projects.

CNC Drilling

CNC Drilling uses rotating drill bits to create cylindrical holes in workpieces quickly and accurately.

A CNC drilling machine controls the plunge rate, depth of cut, and spindle speed based on the input from the CNC program. There are many drilling types of CNC machines available, ranging from manual machines that require an operator to monitor the process, to fully automated systems with built-in safety features. Such systems can be used to produce high-quality results with greater accuracy and precision than traditional hand-drilling techniques.

CNC drilling provides faster turnaround times and more consistent results than manual methods, making it a great choice for those looking for efficiency and reliability in their production processes.

CNC Laser Cutting

This type of CNC machine uses a focused laser beam to cut sheets of different materials with high precision. It is widely used in industries such as aerospace and automotive.

In terms of the type of laser used for cutting, both CO2 and Fiber lasers can be employed. When it comes to choosing the best CNC machine for your project, consider both CNC Laser Cutting and Plasma Cutting. Laser Cutting Machines are the more efficient of the two, but Plasma Cutting can cut materials of greater thickness.

CNC Plasma Cutting

CNC Plasma Cutting uses a plasma torch to quickly and accurately cut through electrically conductive materials. This process is faster and more precise than traditional methods, making it an attractive choice for many industries in need of efficient cutting solutions.

This method can cut metal up to 80mm in thickness, whereas laser cutting can only cut up to 25mm thick. In addition, the electrical discharge from the torch produces less heat than in traditional cutting methods, reducing the risk of warping or distortion in your workpiece.

CNC plasma cutting machines are relatively affordable compared to other CNC machines, making them accessible to smaller businesses or hobbyists. The versatility of these makes them highly desirable for applications such as automotive part production, sheet metal fabrication, and other industrial operations.

CNC Waterjet Cutting

CNC Waterjet Cutting uses a thin jet of water to precisely cut through materials for various applications.

It uses pressurised water and abrasive particles, such as garnet, to create precise cuts with minimal heat-affected zones. It's a great alternative to plasma cutting or laser cutting CNC machines when working with thinner materials.

During operation, the CNC water jet moves along an X-Y axis while blasting out a finely tuned stream of pressurised water at exceptionally high speeds. This allows it to cut intricate shapes and patterns with absolute precision and accuracy.

CNC Grinding

Using a specialised wheel, CNC Grinding is a precision metal removal process that creates finely detailed pieces. This type of CNC machine employs a rotating wheel to cut and shape metals with exacting accuracy. It often involves removing material from a workpiece for sanding, finishing, or polishing purposes. It can be used for various applications, from internal grinding to surface grinding.

CNC Bending Machine

A CNC bending machine is a type of CNC machine that uses computer-controlled presses to bend workpieces into desired shapes. A discharge machine is designed to move and bend the metal as it moves along an axis.

This type of CNC machine is often used for forming simple or complex shapes out of sheet metals, pipes, and other materials. It can be controlled by a computer-operated program that changes the shape of the material with each pass.

With this technology, you can produce products quickly with repeatable accuracy that would otherwise take much longer to fabricate manually.

CNC Electrical Discharge

Electrical Discharge Machines (EDM) use electrical sparks to remove material from - or shape - a workpiece. It operates with high precision, making it ideal for complex designs.

It works by passing an electrical current through a small gap between two electrodes, one of which is the workpiece and the other a tool. This creates sparks that remove tiny particles of metal from the workpiece.

EDMs are most commonly used in three-axis CNC machines and are becoming increasingly popular due to their ability to accurately cut and mould metal into intricate shapes with minimal waste.

CNC Pick and Place Robots

Pick-and-place robots are a type of CNC automation that can quickly and accurately handle small components, allowing for faster production rates. They typically do so using robotic arms to select components from a tray and place them in designated areas.

This process is automated with the help of a computer control system that helps direct the robot's movements. The operator simply programs the machine with instructions for where to pick up and place each component, allowing it to move through its task quickly and accurately.

CNC pick-and-place robots are used in many industries including electronics, automotive, aerospace, medical device manufacturing, and food processing. Their speed and accuracy make them an ideal choice for applications that require precise placement of parts or components.

Multiaxis CNC Machines

Machines such as CNC Milling and CNC Turning vary in the number of axes they have. Here at Link Business, we use a variety of multi-axis CNC machines, allowing us to rotate/move our cutting tools in multiple directions. This ensures that we can meet the bespoke needs of each of our customers.

CNC machines with multiple axes provide more complex capabilities, offering the ability to create complex 3D parts or modify parts from multiple axes. Compare:

- A 2-Axis CNC machine, which is our most basic CNC machine, offering vertical and horizontal movement.

- A 3-Axis CNC machine, which has three axes of movement, allowing for more intricate work.

- A 4-Axis and 5-Axis CNC Machine, which allows for more advanced designs and the ability to produce complex geometries that are unavailable on other types of CNC machine.

Which CNC Machine Should You Use?

We’ve explored a variety of different types of CNC machine, but how do you know which one best suits your needs? When considering which to use, there are several factors to take into account:

a. The Materials to Be Machined

The materials to be machined play a crucial role in determining the suitable type of CNC machine for the job. CNC machines are capable of working on a wide range of materials, including aluminium, copper, steel, titanium, and Inconel. The choice of material will influence your machine choice, the spindle to be selected, and the levels of performance, durability, load bearing, and precision that can be achieved.

b. The Complexity of Parts

The difficulty and complexity of the parts to be machined also play a role in determining the suitable CNC machine. Industries like automotive, aerospace, and medical may require advanced CNC machines with multiple axes and several spindles. These machines allow for manoeuvring, cutting, boring, and shaping of parts controlled through multiple axes.

c. Your Budget

Budget and costs are also important considerations when choosing a CNC machine. The cost of CNC machined parts is determined by the time it takes to manufacture them, multiplied by an hourly rate. Therefore, having a deep understanding of the manufacturing processes involved, such as programming, machine tool setup, de-burring, and inspection, is crucial for accurate pricing.

Overall, which machine you choose should depend on the project you’re working on and the type of precision required.

Here at Link Business, we offer a 24-hour lights-out service, providing services using various types of CNC machine for all applications and budgets. Get in touch today, to learn more about our services which include:

- CNC Machining (Milling, Turning and Sliding Head).

- Tube Bending.

- Laser Cutting.

- Press Braking.

We offer fast turnaround times, high accuracy, and maximum efficiency in production. And our wide range of services allows our customers to choose the most suitable option based on their requirements and budget.

Still not sure which machine best suits your needs? Our expert team is on hand to help you determine the right machining processes based on the requirements of your project.