Link Business provides press braking services as a method of forming a range of components; supplied with a variety of tooling, we can produce many different components to ensure all our customers’ needs are met.

The flexibility of our service means we can achieve this for all product volumes, from prototypes and low-volume orders to high-volume batches.

While we're based in the West Midlands, our press braking services serve customers across the UK.

Get in Touch for a Quote

We pride ourselves on a service which is built around the individual requirements of a project, ensuring we can provide the right solution for a time- and cost-efficient fabrication service. As part of this, we utilise precision CNC press brakes for accuracy and quality of production every time.

CNC Press Brake Services

Our press braking service is undertaken on an Amada CNC press brake machine, which has the ability to fold up to 2.5m in length, with an 80 tonne capacity.

With a vast array of standard and non-standard tooling, we are able to fold most components.

Computer numerical controlled machinery ensures we can produce components with greater accuracy, reliability and repeatability, whilst meeting the agreed timescales of your project.

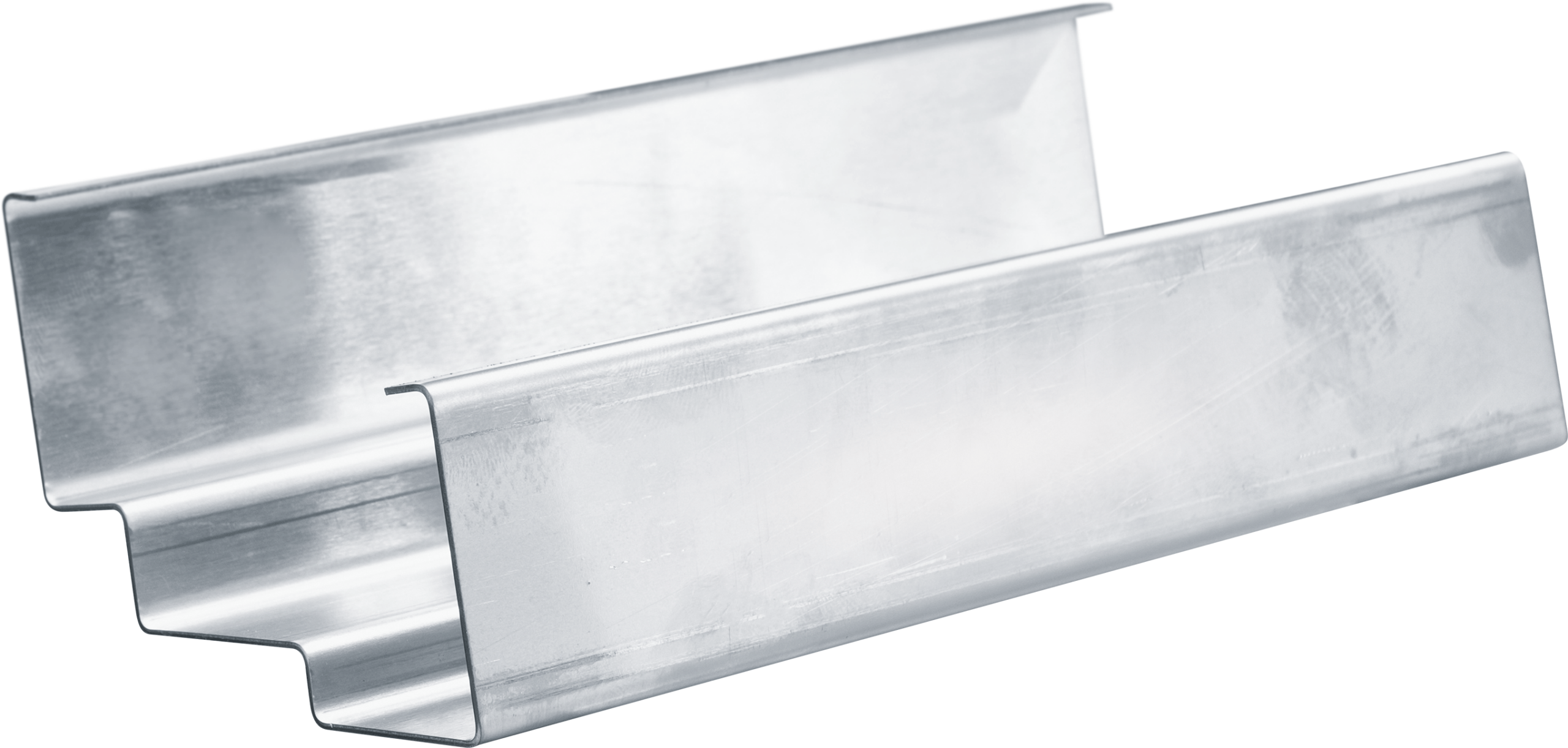

Metal Folded to Your Desired Shape

Link Business’ work is always custom to your project and profile specifications, and our press braking service is no exception.

We fold your components to order, following a consultancy service where our team understands the requirements of your product and can advise on the best fabrication methods to achieve this.

With a great variety of tooling to hand, our press braking services can produce a variety of components.

Press Braking - FAQs

What is press braking?

Press braking is a metal fabrication process that uses a press to bend or shape sheet metal. The metal is clamped between a punch and a die - with the punch applying a force which forms a bend angle along the die’s edge.

The amount of force applied determines the depth and accuracy of the bend.

Press braking is a versatile and cost-effective method used in various industries to create precise and complex shapes, such as brackets, enclosures, and automotive components. Here at Link Business, we utilise CNC technology to deliver press braking services and produce components with greater accuracy.