Are you looking to cut material and trying to decide between fiber vs CO2 laser cutting?

In this article, we'll explore the differences between these two laser cutting techniques. We'll look at the advantages and disadvantages of each method, helping you decide which is best for your project.

Understanding Fiber Laser Cutting

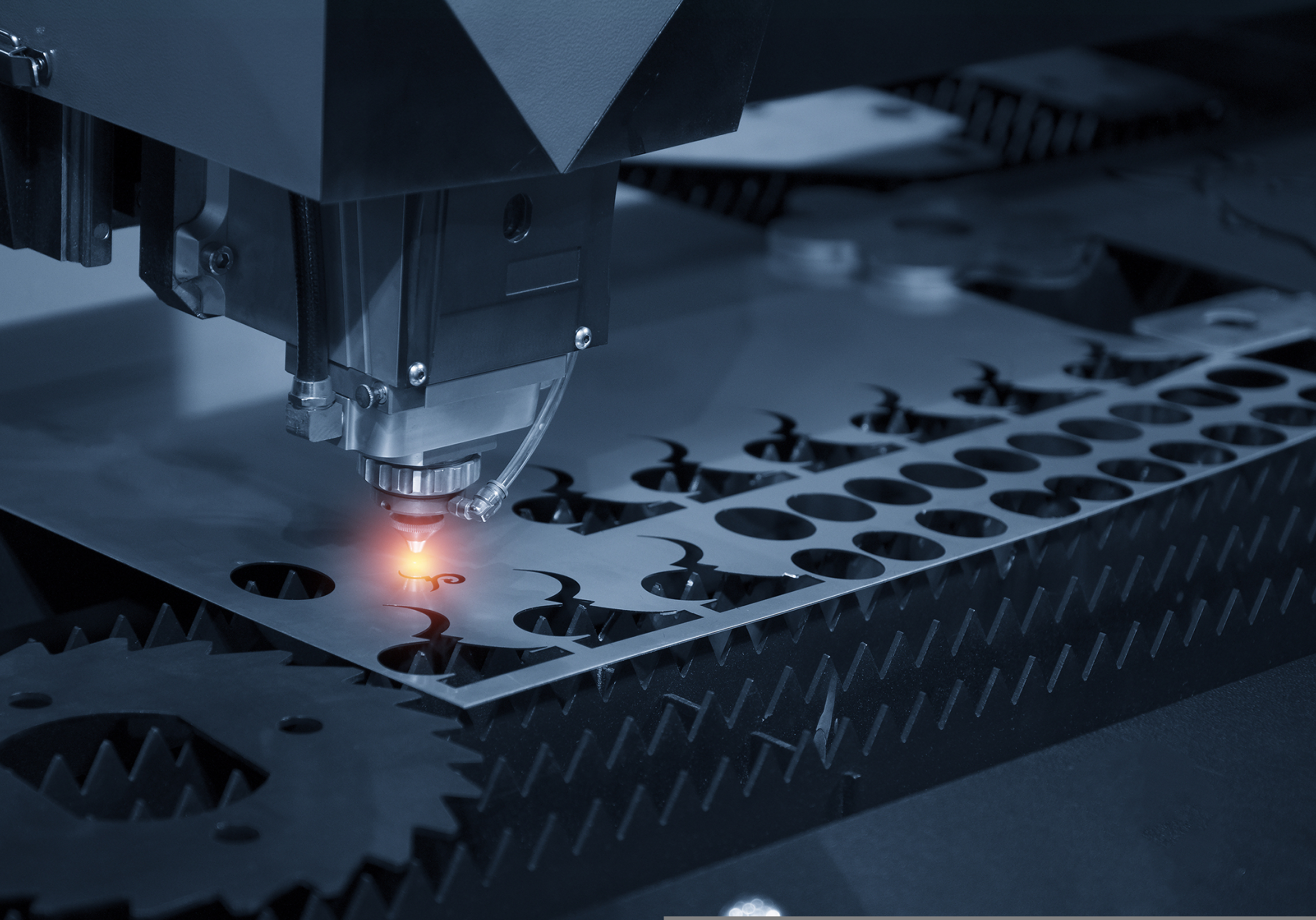

Fiber lasers use a high-powered laser beam that is transmitted through an optical fiber. The laser beam is generated by applying electricity to rare-earth elements, such as erbium or ytterbium; leading to an excitation within the fiber. This causes the emission of photons that form the laser beam, which is then directed onto the workpiece using mirrors and lenses. From there, the focused beam creates a high-intensity spot on the surface of the material, which melts or vaporizes it.

Fiber laser cutting is used for a wide variety of fabrication projects due to its power density, energy efficiency, precision, and reliability. In manufacturing, industrial fiber lasers are commonly used for sheet metal cutting, laser welding, and other applications.

Exploring CO2 Laser Cutting

To understand how fiber lasers differ from their counterparts, we must understand how CO2 laser cutting operates.

CO2 lasers use a mixture of carbon dioxide, nitrogen, and helium gases to generate a laser beam. The laser beam is created when an electric current passes through the gas mixture, exciting the molecules and causing them to emit photons. The photons are then reflected by the mirrors and directed towards the cutting head. The cutting head contains a focusing lens that concentrates the laser beam into a small, intense spot, which melts or vaporizes the material, allowing for a cut.

CO2 lasers are widely used in industries such as automotive, aerospace, and electronics. Due to their longer wavelength, CO2 lasers are better suited for cutting thicker materials like wood, plastics, and metals.

Key Differences Between Fiber and CO2 Laser Cutting

Now that we understand the core features of fiber and CO2 laser cutting, let’s explore the key differences between them.

1. Laser and Source Medium

Fiber lasers employ specially doped optical fibers, such as those doped with rare-earth elements like erbium or ytterbium, as their gain medium. By comparison, CO2 lasers use a combination of carbon dioxide, nitrogen, and other gases.

2. Power Consumption

Fiber laser cutting is far more efficient than its CO2 counterpart. The energy required to power a fiber machine is only 30-50% of that needed for a CO2 laser, while providing higher cutting speeds and superior accuracy.

Furthermore, fiber lasers can last up to 50,000 hours, while a CO2 laser has a life expectancy of around 10,000 hours. This means that fiber lasers require less maintenance and less frequent replacement cycles.

3. Wavelength Variance

Fiber lasers have a shorter wavelength of 1.07 µm, while CO2 lasers have a longer wavelength of 10.6 µm. This difference makes them suitable for different material processing applications.

Fiber lasers are great for cutting thin metals like aluminium and can penetrate materials more effectively. On the other hand, CO2 lasers, with their longer wavelength, are better for thicker metals and non-metals such as wood and acrylic.

CO2 lasers cannot process highly reflective materials like aluminum, steel, copper, and brass; as they cannot absorb the particular wavelength of light emitted by CO2 lasers. As a result, it is not easy to cut shiny metals using low-powered CO2 lasers.

In contrast, fiber lasers have a much shorter wavelength. They can penetrate through most materials and are readily absorbed by a wide variety of materials.

4. Cutting Speed and Efficiency

Fiber lasers are faster and more efficient than CO2 lasers, making them the preferred choice for many industrial applications.

This is because the shorter wavelength of the fiber laser allows it to concentrate more energy on the material, resulting in a higher cutting speed. However, when it comes to cutting thicker materials, CO2 lasers are often more efficient compared to fiber laser cutters.

It’s crucial to take into account other factors like material properties, desired cutting quality, and specific application requirements when selecting a suitable laser system for your project needs.

Evaluating Fiber Laser cutting

The Advantages of Fiber Laser Cutting

When compared to their CO2 counterparts, fiber lasers offer several advantages that make these techniques the preferred choice:

- Increased Efficiency: Fiber laser cutting technology allows for faster cutting times and greater precision.

- Greater precision: With fiber lasers, intricate and precise cuts can be made with minimal errors, ensuring high-quality finished products.

- Faster cutting times: Fiber lasers are known for their rapid cutting speeds, reducing production time and increasing productivity.

- Reduced material waste: The precise nature of fiber laser cutting minimises material waste, leading to cost savings and a more sustainable manufacturing process.

- Lower operational costs: Fiber laser cutting machines require lower energy consumption, resulting in reduced utility bills and operational costs.

- Reduced downtime: The reliability and durability of fiber laser cutting machines contribute to decreased downtime, maximizing production uptime and profitability.

Overall, fiber laser cutting offers a unique combination of cost-savings, precision, and productivity that traditional CO2 laser cutting can't match.

The Disadvantages of Fiber Laser Cutting

Despite these advantages, fiber laser cutting also has some drawbacks worth considering:

- One of the main issues is limited material compatibility. While most metals can be cut using this method, certain materials may not be compatible with the process.

- Initial investment costs: Start-up costs for fiber laser cutting are much higher than those of CO2 laser cutting.

It's important to research both types of laser cutting to determine which best meets your needs. Here at Link Business, we aim to account for all requirements; but the decision ultimately depends on the specific needs of your project. We recommend getting in touch with our expert team to discuss manufacturing feasibility depending on your materials and specifications.

Evaluating CO2 Laser Cutting

The Advantages of CO2 Laser Cutting

While CO2 techniques have fallen out of favour with fiber technology, the use of these machines does still provide some benefits:

- Material versatility: CO2 lasers are extremely versatile and often still used to cut thick non-metals like plastics, wood, acrylic, fabric and other organic materials.

- Excellent edge quality: CO2 lasers offer excellent edge quality due to their larger spot size. Regardless of the sheet thickness, they consistently provide a smooth cut edge. This quality becomes more pronounced as the sheet thickness increases.

The Disadvantages of CO2 Laser Cutting

Despite these advantages, there is a reason that they are now less favourable to their fiber alternatives:

- Speed: Especially when it comes to thinner materials, fiber lasers are significantly quicker than CO2 types.

- Costs: CO2 lasers require significantly higher power consumption and operating costs. As such, fiber lasers are often able to provide an indistinguishable cut at a much cheaper cost.

- Maintenance: CO2 lasers are more prone to wear and tear than fiber lasers and can require more frequent replacement of parts. As such, CO2 machines are much less reliable and more likely to have downtime.

Fiber vs CO2 Laser Cutting: Which Technique to Choose?

While CO2 laser cutting is occasionally worthwhile, it should be clear by now that fiber laser cutting is a far superior solution. It can produce a high-quality and reliable cut at a fraction of the price it would for its CO2 counterparts.

Are you looking for laser-cutting services? Here at Link Business, we provide subcontract fiber laser cutting services - so that you can benefit from the latest laser cutting technology without any of the upfront costs. We use a Bystronic Fiber 6Kw Laser Machine, which allows for components from a few millimetres up to 3m x 1.5m x 12mm with a minimal heat-affected zone.

We are happy to work with all product sizes and volumes within our capabilities; and can cut a range of metals, plastics and other materials. Our cuts are done with accuracy and efficiency. And, as we utilise CNC technology, we can offer a 24-hour lights-out service, to meet tight deadlines and turnaround times.