Whether you're in the manufacturing industry or a DIY enthusiast, laser cutting offers countless advantages. From its ability to create intricate designs to its speed and accuracy, it's no wonder laser cutting is becoming increasingly popular.

Read on to learn how it could revolutionise your projects.

What is Laser Cutting?

Laser cutting is a process that utilises a laser to precisely cut materials. The laser beam is very narrow, typically under 0.0125 inches in diameter, and can be even smaller depending on the material thickness. This beam is directed through optics and controlled by computer numerical control to cut through materials with high precision.

The cutting process begins with a piercing process, where a high-power pulsed laser creates a hole to initiate the cutting. This controlled and efficient cutting process allows for intricate and accurate designs to be created on a wide range of materials.

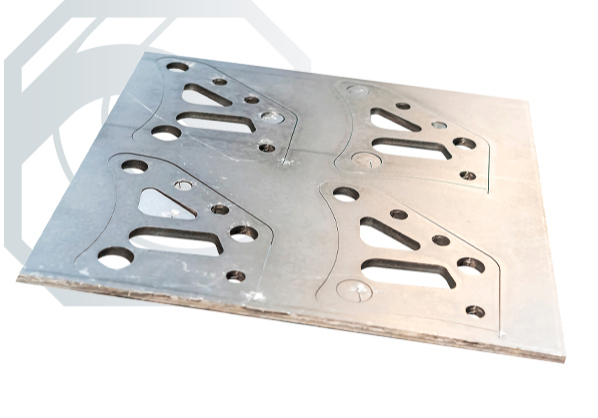

It can be used to cut materials such as metal, wood, acrylic, fabric, and more - allowing for the creation of complex shapes and designs that may not be possible with traditional cutting methods. It is commonly used in various industries, like automotive, aerospace, and electronics.

In addition to cutting, laser cutting machines can also be used for etching and engraving. This allows for the customisation of products and the addition of intricate details.

Whatever you’re using it for, laser cutting is a versatile and efficient process that continues to evolve and find new applications in various industries.

Fiber vs CO2 Laser Cutting

The most common laser cutting techniques involve using either a Fiber or CO2 machine. The former is a new and emerging technology which is slowly replacing its CO2 counterpart.

In Fiber laser cutting, the transmission of light to the cutting head occurs through Fiber optics, overseen by the CNC system. Within the cutting head, the laser is discharged from the tip of the Fiber optic cable and subsequently redirected through an array of focal lenses, resulting in a highly precise focal point on the surface of the material.

By comparison, with CO2 laser cutting, the beam is generated by exciting carbon dioxide gas with an electrical discharge, resulting in the creation of photons. These photons are then directed through a series of mirrors to focus the beam into a small spot. The focused laser beam is then guided by a computer-controlled system, which determines the desired cutting path. The beam has an optimal point of focus and intensity, which allows for precise cutting.

Here at Link Business, we use a Bystronic Fiber 6 Kw laser cutting machine, which allows us to cut various components - from a few millimetres up to 3m x 15m x 12mm. Using this machine brings a host of benefits. The advantages of Fiber machines include:

- Having a smaller and more focused spot size, resulting in finer and more accurate cuts. This is especially beneficial when working with intricate designs or delicate materials.

- Cutting with minimal surface roughness - their focus also gives them a greater depth of cut; allowing for intricate designs and fast cutting speeds.

- These machines are more energy-efficient than CO2 lasers, making them more cost-effective and better for the environment.

- Fiber lasers are highly reliable and efficient, requiring minimal maintenance. This means our machines have very limited downtime and are a reliable choice for your project.

- The ability to cut a wide range of materials. Here at Link Business, we work with a vast variety - including metals and plastics.

Want to learn more about the advantages of our Fiber laser cutting services? Read on.

The Advantages of Laser Cutting

As a fabrication technique, laser cutting offers a variety of advantages which make it a common choice in the industrial and manufacturing industry.

Precision and Repeatability

When it comes to cutting materials, Plasma or Water cutting was traditionally seen as more cost-effective than laser cutting. But these methods don’t provide anywhere near the same quality of cut.

Compared to the alternatives, laser cutting provides a higher level of precision and repeatability, ensuring accurate cuts every time. These machines have the capability to provide dimensional accuracy of approximately 0.0005 inches, which is unmatched by traditional methods.

This level of precision allows for reduced material waste, as the cuts are incredibly accurate and minimise errors. Additionally, this offers excellent repeatability, meaning that the same design can be replicated consistently without any variation. This is crucial for industries that require repeated production of identical components.

Material Versatility

You can expand your manufacturing capabilities with our laser cutting services, as it allows for the precise and consistent cutting of a wide range of materials.

Regardless of whether you’re working on a detailed design or a larger cut, and regardless of whether you’re working with a thick or delicate material - our laser cutting offers excellent repeatability, ensuring consistent results even for large production runs.

Speed and Efficiency

Compared to traditional mechanical cutting methods, laser cutting is much quicker, allowing for faster production times and increased productivity. The precision and accuracy of laser cutting also contribute to its efficiency, as it eliminates the need for manual adjustments and reduces material waste.

As we laser cut a variety of materials, we can easily vary the design and materials requirements using our CNC technology - to ensure that we meet the needs of your project quickly and efficiently.

Minimal Heat Affected Zone

With laser cutting, the focused laser beam generates intense heat only in the small area where the material is being cut, and because these machines operate at high speeds, the exposure time of the material is minimal. As a result, there is a much smaller HAZ compared to other cutting methods.

Consequently, when using laser cutting, the surrounding material is less affected by heat, preserving its properties and structural integrity.

Contactless Cutting

In addition to reducing the HAZ, laser cutting is contactless - as only the beam comes into contact with the material (and there is no direct contact between the cutting tool and your materials). Thus, no mechanical friction could occur during the cut which could wear your tools or materials. This also allows for a clean, smooth and precise cut

Customisation and Personalisation

You can easily personalise and customise your designs with a laser cutter, turning your dream design into a reality. Whether you want to create intricate shapes, detailed patterns, or even cut holes with precision, a laser cutter can make it happen.

With a laser cutter, you have the power to bring your creative ideas to life and make them truly one-of-a-kind.

Automation and Integration

With the integration of laser cutting and CAD software, we can automate your production process.

This automation allows us to provide a 24-hour, lights-out service - leading to faster and more efficient production times for your products. It also allows for increased accuracy; as our use of CAD software ensures precise cutting, reducing human error and improving the quality of our output.

To summarise, laser cutting is a powerful tool that can be used in a range of industries and applications. Its precision and accuracy allow for intricate designs and cuts, while its speed and efficiency increase productivity.

Want to reap some of these benefits? Here at Link Business, we employ the latest technology to provide laser-cutting services for a wide range of materials. Working to improve the accuracy, repeatability, and finish of your cut - we are happy to work with all product sizes within our capabilities and product volumes. Get in touch, to find out more.